XX Car Factory Automotive Painting Line Upgrade

Issues identified at XX car factory automotive painting line:

- Currently, QR codes are read visually, and their data cannot be reused.

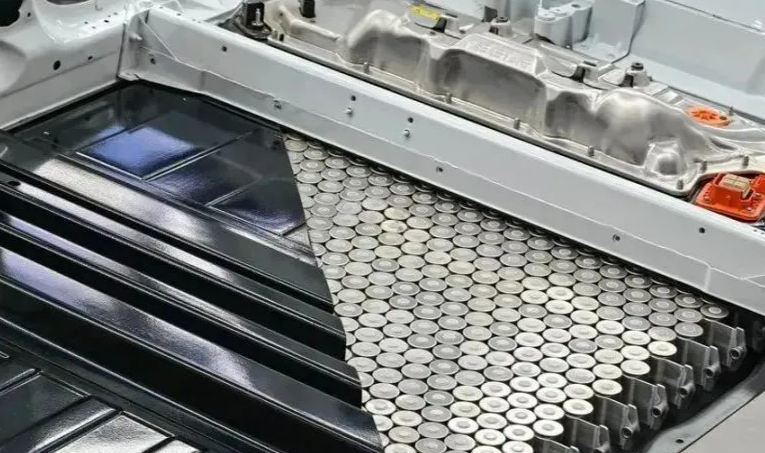

- Due to on-site spray painting processes, QR codes become obscured by paint and cannot be recognized.

- Since the data cannot be modified, it is impossible to communicate to the next process what specific operations should be performed.

Provided Solution:

- Each component is affixed with a unique RFID electronic tag.

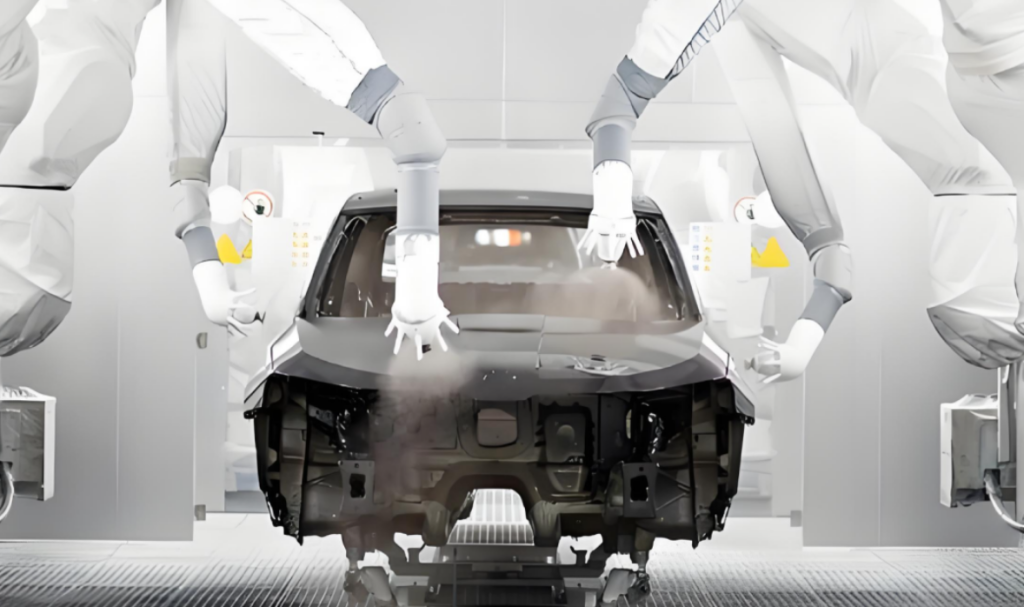

- At the production line entrance or key processing points, RFID readers capture information from tags entering their range. Based on the product details stored within the tag (such as model, specifications, etc.), the production line automatically determines which assembly line or processing station the item should proceed to. If the line incorporates automated sorting capabilities, the RFID tag data directly instructs sorting equipment to route the item to the correct production line or workstation.

- Through integration with systems such as PLC and MES, RFID technology enables automation and intelligent operation of production lines. For example, when a component arrives at a processing station, the reader automatically captures its electronic tag information and transmits it to the PLC system. Based on this data, the PLC system controls the operating parameters and processes of the machining equipment, enabling automated production. Concurrently, the MES system enables real-time monitoring and analysis of production data, facilitating timely adjustments to production schedules and optimization of manufacturing workflows.

- Based on the product information stored within the RFID tags, the production line automatically adjusts the process parameters of the processing equipment, such as temperature, pressure, and time. This ensures that each product is processed according to its specific requirements, thereby enhancing product quality and consistency.

Applied Products Information-RT78 Series Product Features:

- The reader features a high-strength aluminum alloy housing, offering fast identification speed, high accuracy, moderate reading distance, and convenient networking capabilities.

- Rich interfaces and protocols: RS232, RS485, Ethernet. Supports industrial protocols including Modbus RTU, Modbus TCP, Profinet, EtherNet/IP, and EtherCAT.

- High protection rating: IP67-rated for waterproofing, corrosion resistance, and interference immunity, ensuring reliable operation in harsh industrial environments.

- Standard protocol: Operates at 902MHz–928MHz frequency range, compliant with EPC Global Class 1 Gen 2/ISO 18000-6C standards.