Customized Roll RFID Tags Applied to Roll Lifecycle Management at XX Steel Mill

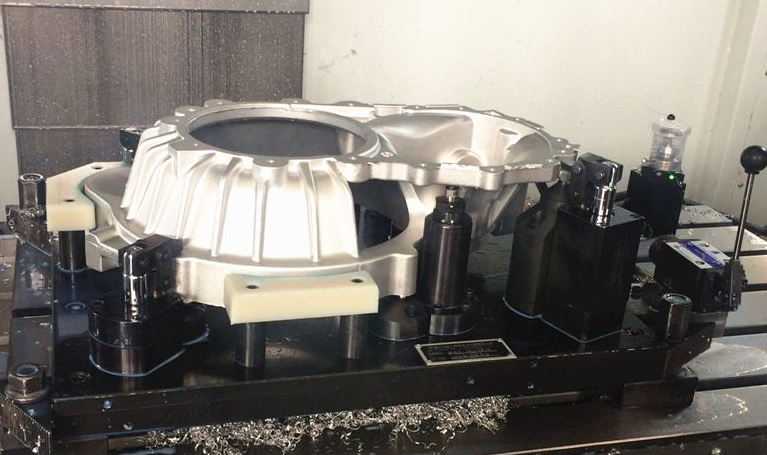

Custom-designed specialty roll RFID tags were developed for the client’s products based on their requirements. These RFID tags feature high-temperature resistance and corrosion resistance, enabling them to withstand the harsh operating conditions at the client’s site.

These RFID tags serve as unique identifiers for the customer’s rolling mill products. Embedded upon completion of the rolling mill’s production, they track the product’s usage within the steel mill from delivery to the customer through to the rolling mill’s end-of-life.

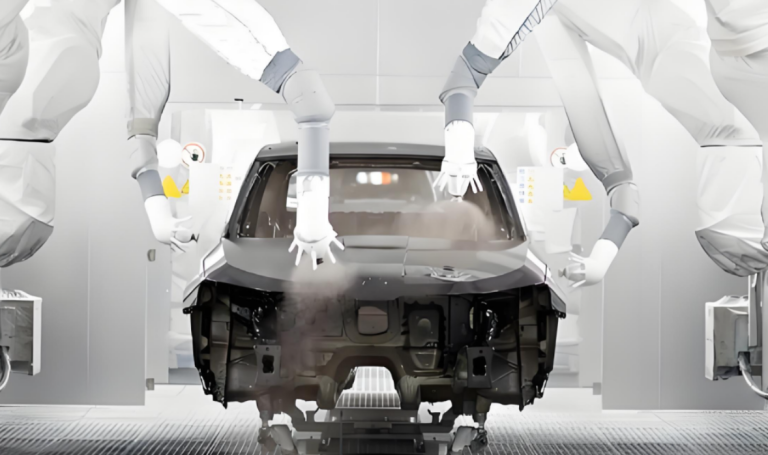

The introduction of RFID technology has replaced the manual recording of roller numbers previously used by customers to manage roller warehousing, inventory, and after-sales maintenance. Since RFID tags require no human intervention for identification, enterprises can achieve automated, unmanned operations by integrating with automated equipment such as industrial robotic arms. This significantly enhances the efficiency and security of roller product management for customers.

RFID roll tags feature high-temperature and corrosion resistance, adapting to the harsh operating environments of rolling mills.

Capable of penetrating water and oil contamination, these tags offer extended read ranges and are resistant to damage. They integrate seamlessly with robotic arms to enable fully automated, unmanned production facilities.