RFID Products Applied to Precision Tool Management at XX Tool Factory

Issues identified at XX tool manufacturing factory:

- Manual data entry has a high error rate: one error occurs per hundred critical inputs, easily leading to operational accidents and defective products.

- No records exist for tool damage or maintenance. Paper documents are prone to surface damage, resulting in incomplete information. Lacking daily maintenance checks and usage logs, workers can only estimate tool life based on experience.

- Separation of machine control panels from tool loading stations prevents visual tool location verification, significantly increasing management complexity during non-standard tool changes.

Provided Solution:

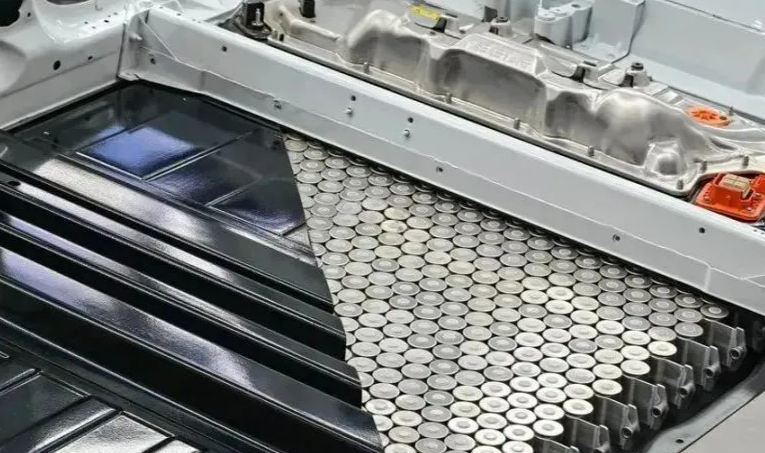

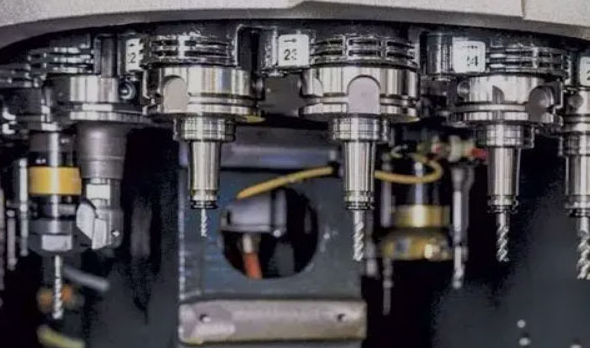

Each cutting tool is embedded with an electronic chip (RFID tag) that stores detailed tool information and operational records. When the tool magazine turret requires a specific tool for processing, it must determine whether that tool corresponds to the component being machined. A nearby reader then accesses the chip to retrieve the tool’s information and verify its suitability for the current machining operation. Additionally, before and after tool replacement, the reader writes the operating duration and maintenance records to the electronic tag. The backend system also automatically assesses the tool’s remaining lifespan, suggests optimal usage duration, compares against inventory levels, and alerts the warehouse to replenish stock.

RFID technology fundamentally resolves issues such as information gaps, inefficiency, and safety hazards in traditional tool management through digitalized, automated management models. Chenkong Intelligent’s solution utilizes electronic tags as carriers, integrating card readers with backend systems to establish a fully intelligent system encompassing “tool identification – data interaction – lifespan prediction – inventory management.” This comprehensive intelligent system is not only applicable to precision manufacturing but also provides replicable practical experience for deepening the application of industrial IoT technology in tool management scenarios. In the future, as RFID technology undergoes cost optimization and performance upgrades, its application potential in scenarios such as multi-variety small-batch production and flexible manufacturing will be further unleashed, driving the continuous evolution of tool management in manufacturing toward intelligent and unmanned operations.

Applied Products Information-RT102ANS Series Product Features:

- A high-frequency RFID tag reader based on radio frequency identification technology, compact and easy to install. Users can read tags simply by receiving data through RS232/RS485 or Ethernet communication interfaces, without needing to understand complex radio frequency communication protocols.

- Standard Protocol: Operating frequency of 13.56 MHz, compliant with ISO 15693 standards.