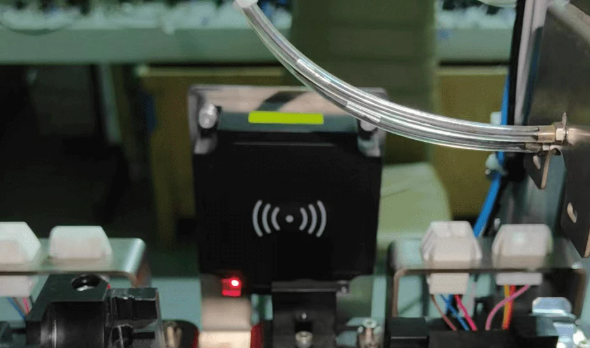

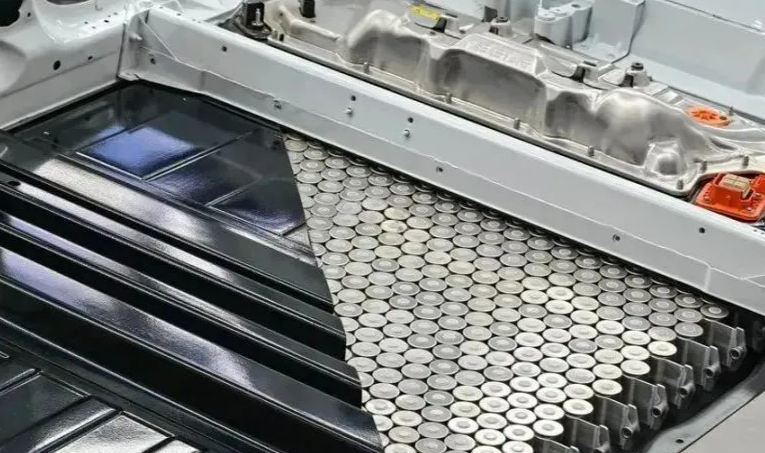

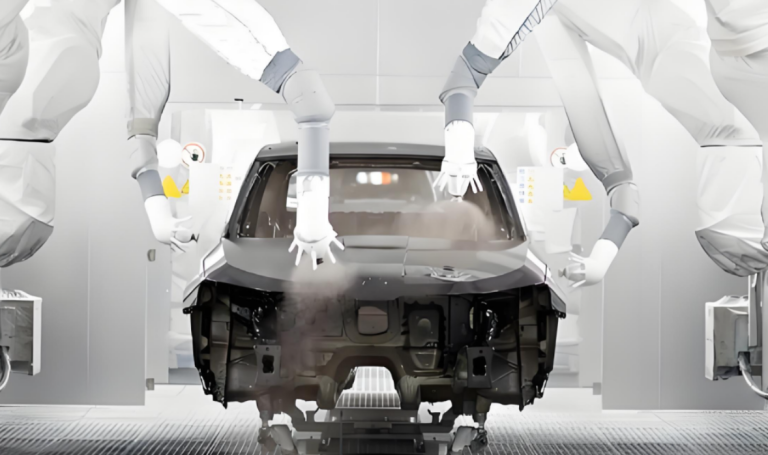

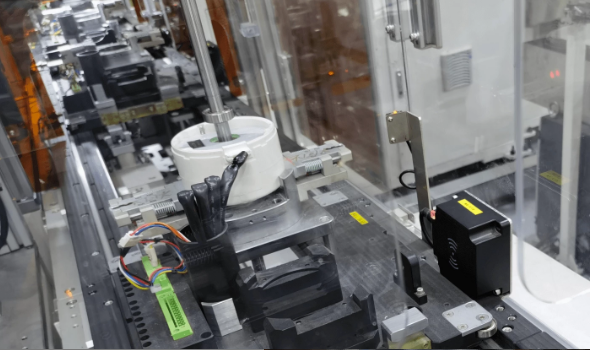

RFID Technology Applied to an Electric Motor Company’s Automated Assembly Line

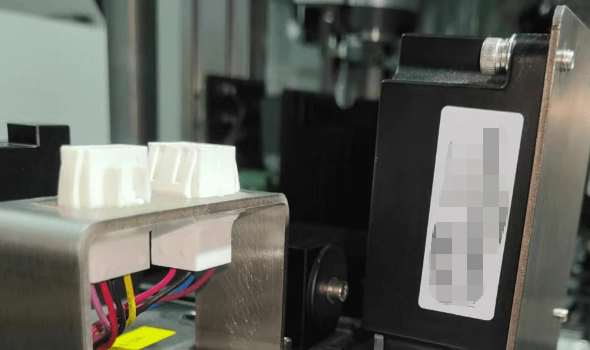

Industrial readers have been successfully deployed on an automated assembly line at an electric motor manufacturer. Utilizing RFID technology, they identify each workflow step in motor assembly. The application of RFID readers on the motor assembly line offers the following advantages:

- Supports Modbus TCP Protocol

By supporting the Modbus protocol, it reduces the workload for customer secondary development and helps customers quickly master the communication between RFID readers and PLCs. - Supports PoE Power Supply

Industrial readers utilize PoE technology, enabling a single network cable to handle both data transmission and device powering, thereby reducing on-site implementation efforts. - Superior Reading Performance with High Sensitivity

Readers deliver outstanding read/write capabilities, adapting to high-speed industrial RFID tag reading in automated production line environments. - Exceptional Stability

All products undergo rigorous testing to ensure reliability in complex field conditions.