Application of RFID Anti-Metal Tags in Steel Sleeve Management

The customer’s original management method involved mechanically engraving text or alphanumeric codes onto the surface of the sleeves to identify the product. Subsequently, manual records were kept at each stage of the product’s application process, with these records periodically entered into the ERP system.

The drawbacks of this approach include the following points:

- Industrial sites are often dirty with heavy oil contamination, frequently obscuring stamped serial numbers on sleeves after removal. Manual wiping is required to reveal them, and dim factory lighting necessitates flashlights even during daytime to read the markings.

- All records are manually handwritten, resulting in low efficiency, illegible handwriting, and high error rates.

- There is a time lag between data recording and system entry. Moreover, the tedious nature of data entry makes it difficult to ensure accuracy.

- Paper documents are difficult to preserve, complicating the process of retrieving and comparing historical records later.

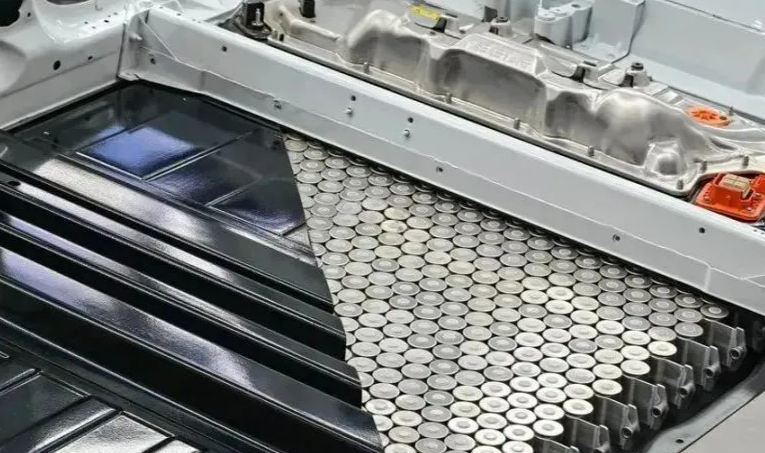

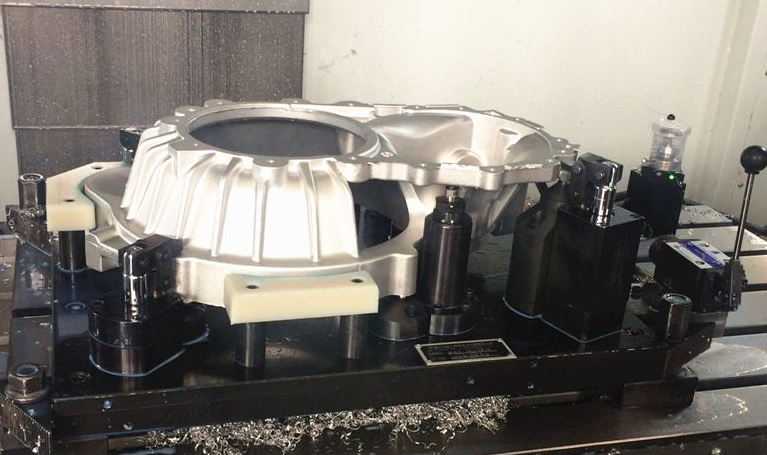

The company provides customized design services based on client requirements, developing a specialized label product and corresponding reading equipment. This solution manages steel sleeves used at client sites through full lifecycle management. An RFID specialty label embedded within each sleeve records its unique ID number, replacing the previous mechanical stamping identification method. From tag embedding through customer delivery, warehousing, inventory, issuance, machine deployment, maintenance, and disposal—the system tracks the sleeve throughout its entire lifecycle until final decommissioning.

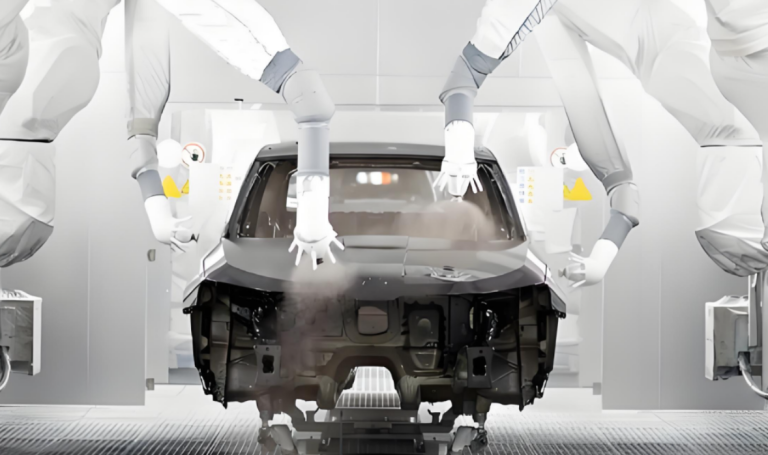

After sleeve production and processing are completed, embed the label. Upon arrival at the customer site, read the label to complete inventory entry via the warehouse management software system. When issuing the sleeve, read the label to complete inventory removal. When the sleeve arrives on-site for machine use, the RFID reader near the machine can read the sleeve’s information, record its current status, and transmit the data in real time to the backend management software.

In the sleeve storage area, RFID handheld terminals are used to complete inventory checks of sleeves. When maintenance is required, the tag information is read. After maintenance is completed, the maintenance record is linked to the tag ID and saved to the system database, finalizing the maintenance process. The entire workflow achieves paperless operation with real-time data collection, eliminating manual data entry. Only reading and binding are required. Additionally, sleeve data retrieval is exceptionally convenient and efficient.