Custom-designed tower crane RFID tags applied in tower crane management project

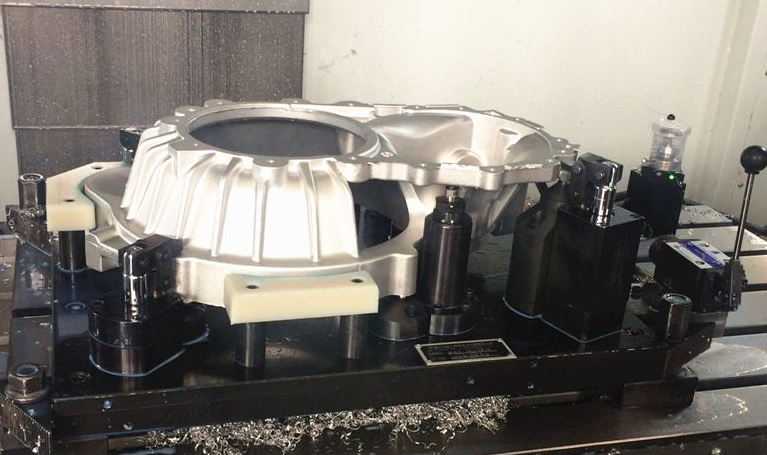

Custom-designed specialty RFID tags were developed to meet client requirements for on-site deployment. These tags achieve an IP68 protection rating, featuring a polymer plastic casing that resists outdoor UV exposure and prevents shell degradation. They withstand harsh environmental conditions at client sites, delivering an outdoor service life of 10-15 years.

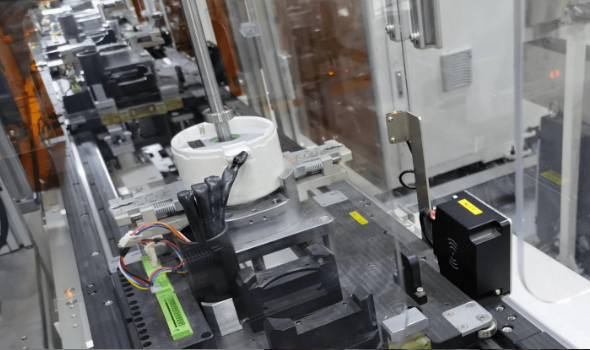

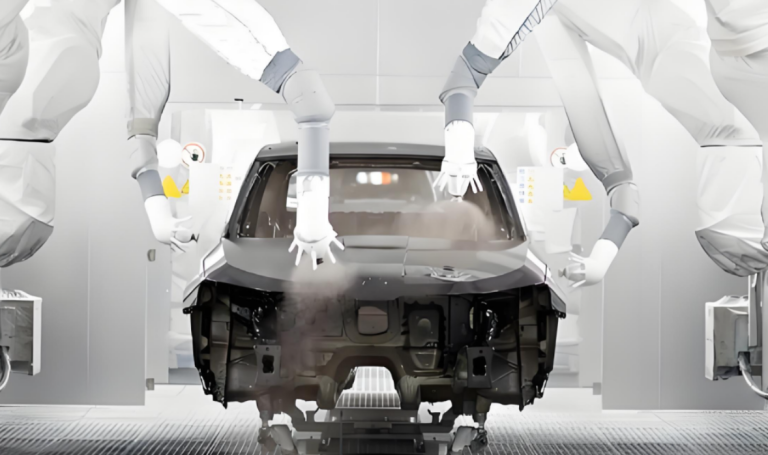

The tower crane RFID tags have been successfully deployed in the RFID tower crane management system of China’s largest tower crane rental enterprise, managing tens of thousands of tower cranes nationwide. They serve as data identity markers throughout the customer’s management processes—including component warehousing, inspections, on-site installation, and dismantling—enhancing management efficiency and elevating safety standards for construction operations.

Due to the prolonged outdoor operation of tower cranes and the complex, variable conditions at construction sites—ranging from extreme cold to intense heat, dry to humid environments, and coastal corrosion—the operating conditions for labels are exceptionally harsh. Based on the specific application environments of our clients’ labels, we have implemented specialized designs and customization, introducing a customized RFID tower crane label/RFID tower crane chip. This solution effectively mitigates the impact of challenging field conditions on client operations.

Features of our custom tower crane RFID chips/tower crane RFID tags/tower crane RFID chips:

- Withstands high and low temperature cycling in long-term outdoor environments

- Resistant to rainwater corrosion

- Resistant to UV radiation from outdoor sunlight

- Anti-aging waterproof and dustproof

- Chip employs high-stability bonding process for vibration resistance

- Label designed for 10-15 year service life in outdoor environments

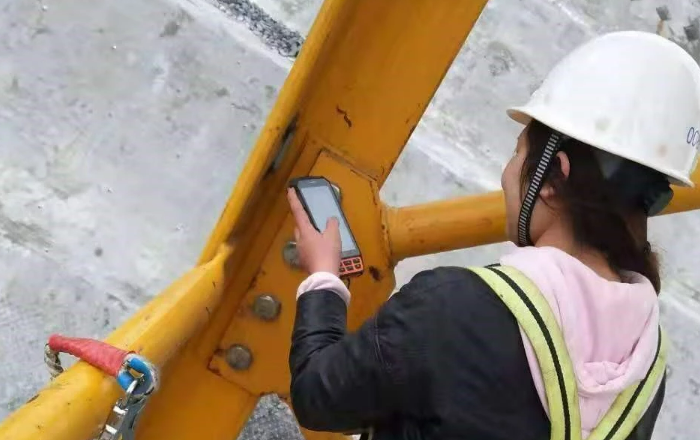

After implementing RFID technology, the client has enhanced the efficiency and accuracy of asset management in tower crane component warehousing and inventory counting. By integrating RFID technology with software systems during on-site installation and dismantling processes, the entire workflow has been standardized, regulated, and digitized, thereby improving safety during tower crane construction operations. Subsequent on-site inspection tasks have also been digitized and informatized, with inspection personnel using RFID handheld terminals to conduct regular tower crane inspections.