Application of RFID Technology in XX Parts Manufacturing Plant

Issues identified at a component machining site:

- Manual barcode scanning and paper-based recording result in a 15%-20% error rate for production data collection, with each product taking up to 30 seconds to record.

- The traditional traceability system relies on barcodes and manual data entry, leading to data delays and information gaps.

Provided Solution:

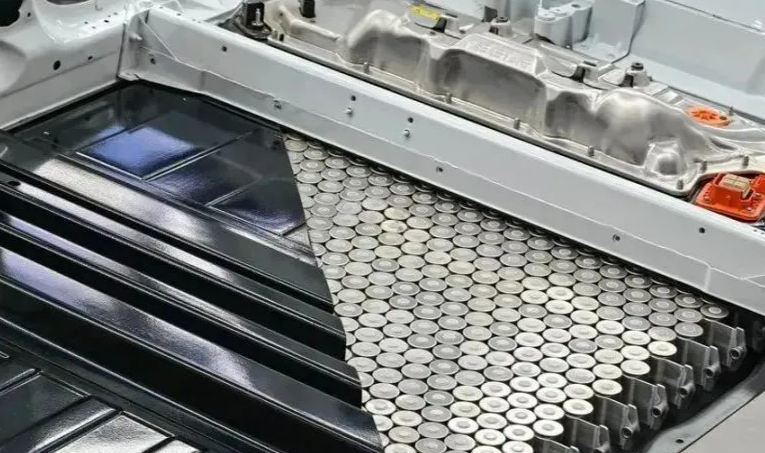

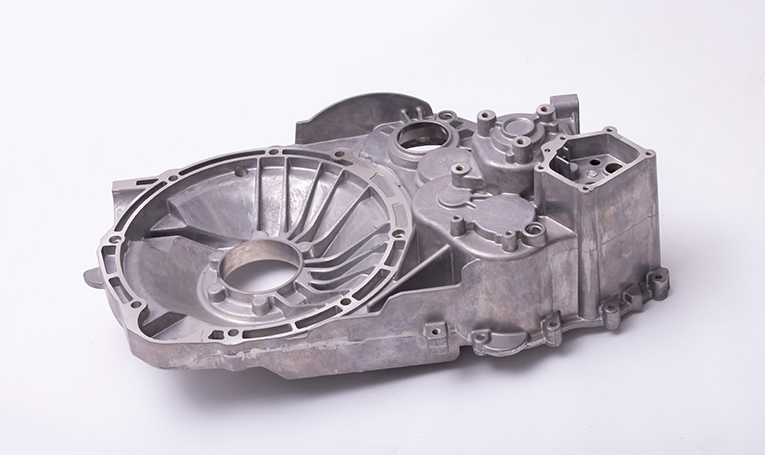

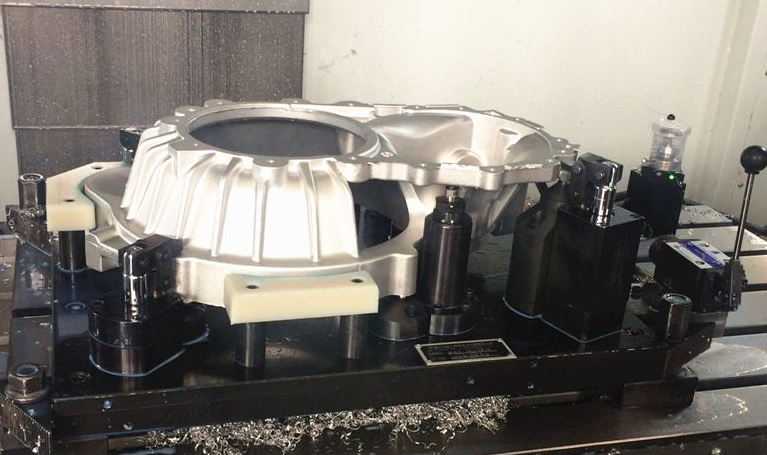

- Tag Selection: For metal transmission housings, anti-metal RFID tags are employed to ensure stable operation in environments ranging from -40°C to 200°C.

- Reader Configuration: Fixed readers with strong anti-metal interference capabilities are deployed at 12 critical points including machining centers, cleaning lines, and inspection stations.

- RFID readers integrated into machining center control cabinets automatically read process parameters (e.g., cutting depth, coolant flow rate) from tagged workpieces upon entry. These parameters are transmitted to the machine tool PLC. Upon successful validation, the system triggers automatic tool change procedures.

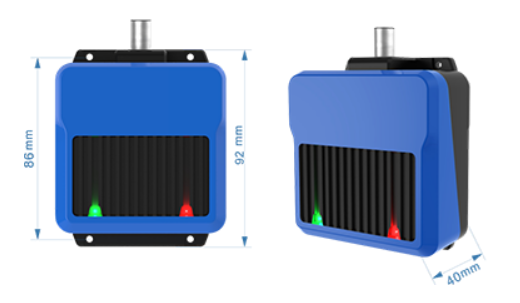

Applied Products Information-RTFR08 Series Product Features:

- High Integration: A 3-in-1 high-frequency reader integrating antenna, amplifier, and controller.

- Diverse Interfaces and Protocols: Supports RS232, RS485, and Ethernet. Compatible with industrial protocols including Modbus RTU, Modbus TCP, Profinet, EtherNet/IP, EtherCAT, and TCP/IP.

- High Protection Rating: IP67-rated for waterproofing, corrosion resistance, and interference immunity, suitable for harsh industrial environments.

- Standard Protocol: Operates at 13.56 MHz, compliant with ISO 15693 standards.