RFID Technology Empowers XX Factory’s Bathroom Fixtures Production Line

Issues identified at a client’s on-site bathroom fixture production line:

- Manual recording of critical data such as mold usage counts and injection molding parameters resulted in an error rate as high as 15%, causing delays in equipment maintenance planning;

- Surface treatment processes like electroplating and PVD coating relied on manual verification of fixture information, with each batch taking over 2 hours to complete;

- Barcode labels are susceptible to corrosion from plating solutions, necessitating manual review of paper records during quality incident investigations—averaging 3 days per case.

Provided Solution:

- Process parameters such as mold temperature and pressure (integrated via sensors + RFID tags), Product yield rate per shift (linked with the MES system), Mold maintenance history (updated by maintenance personnel using handheld terminals).

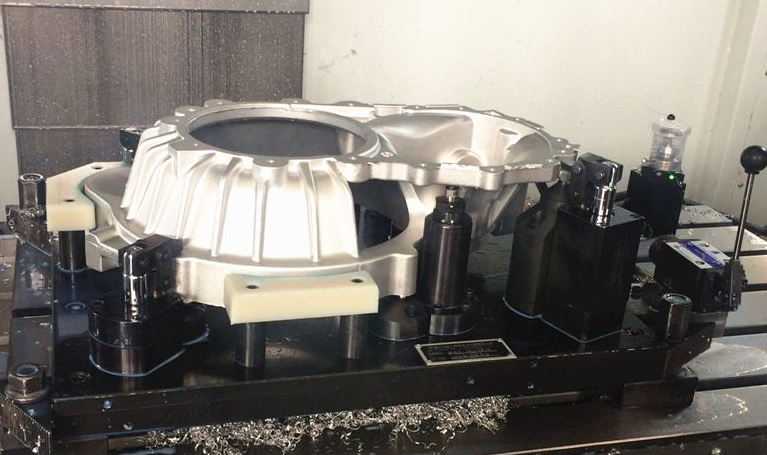

- Hanging Process: The system automatically assigns fixture numbers, linking them to product models and batch information. Process Treatment: After each operation, the reader/writer records processing time, operator, and equipment parameters. Post-Hanging Inspection: Utilizing load cells + RFID comparison, it automatically calculates coating thickness pass rate. Integrate RFID readers into the machining center control cabinet. When tagged workpieces enter the workstation, the system automatically reads process parameters from the tags.

- RFID readers integrated into machining center control cabinets automatically read process parameters (e.g., cutting depth, coolant flow rate) from tagged workpieces upon entry. These parameters are transmitted to the machine tool PLC. Upon successful validation, the system triggers automatic tool change procedures.

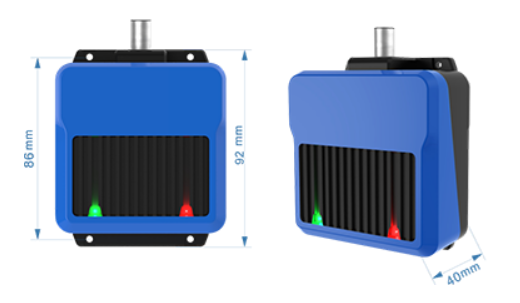

Applied Products Information-RTFR08 Series Product Features:

- High Integration: A 3-in-1 high-frequency reader integrating antenna, amplifier, and controller.

- Diverse Interfaces and Protocols: Supports RS232, RS485, and Ethernet. Compatible with industrial protocols including Modbus RTU, Modbus TCP, Profinet, EtherNet/IP, EtherCAT, and TCP/IP.

- High Protection Rating: IP67-rated for waterproofing, corrosion resistance, and interference immunity, suitable for harsh industrial environments.

- Standard Protocol: Operates at 13.56 MHz, compliant with ISO 15693 standards.