Application of RFID Equipment in the XX Cylindrical Battery Production Line

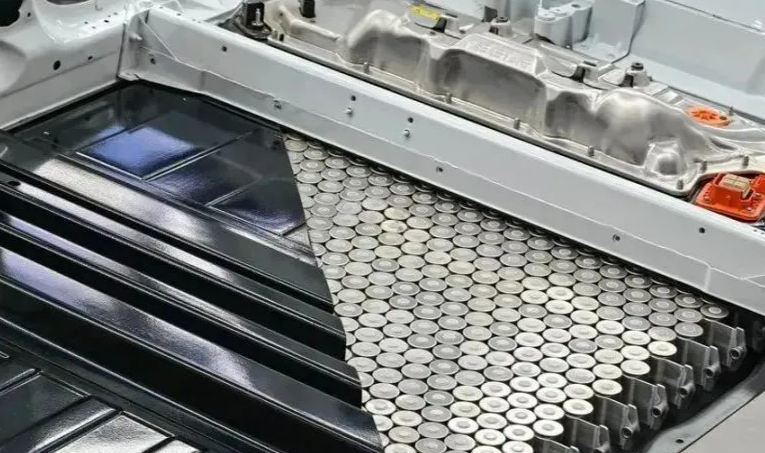

As a core component in the new energy sector, cylindrical batteries demand high levels of automation, precision, and environmental adaptability in their production process. In cylindrical battery production lines, traditional manual recording and barcode recognition methods face multiple challenges.

Issues identified at customer site:

- Harsh Environmental Conditions: High temperatures, electrolyte corrosion, and vibration interference during drag chain conveyor operation cause traditional barcodes to become soiled, detached, or otherwise unreadable.

- Unstable Recognition Surface: Traditional barcode scanning requires fixed positioning, but the rotational movement of cylindrical batteries during production and transport leads to poor recognition rates.

- Process Complexity: From electrode winding and cell assembly to electrolyte filling and encapsulation, tracking cell batches, process parameters, and equipment status is essential. Manual recording is inefficient and error-prone.

- Quality Traceability Requirements: The new energy industry demands strict battery safety and consistency. Real-time, comprehensive traceability of individual cell lifecycle data is required—a challenge traditional methods struggle to meet.

For the unique operating conditions of cylindrical battery production lines, the company introduces an unparalleled RFID solution featuring cylindrical battery tray RFID tags—an irreplaceable alternative to traditional identification methods.

- Non-visual and Anti-interference Recognition: No optical alignment required; reads tags through non-metallic obstructions like insulation layers, suitable for material handling scenarios with densely stacked drag chain cables and high-speed movement.

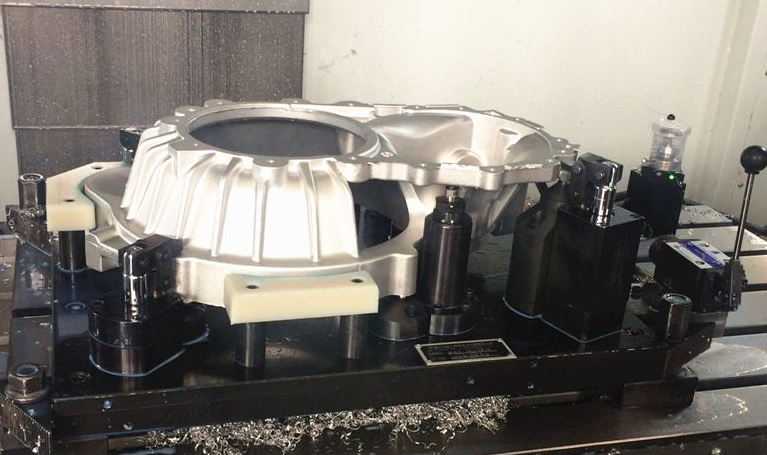

- Extreme Environment Adaptability: Cylindrical battery tray cup RFID tags withstand high-temperature processes like drying and hot pressing; IP67-rated protection resists electrolyte splashes and high-pressure washing.

- No Fixed Identification Surface Required: Cylindrical battery tray cup RFID tags enable 360° dead-angle-free recognition with RFID, ensuring precise identification regardless of tray cup rotation during operation.

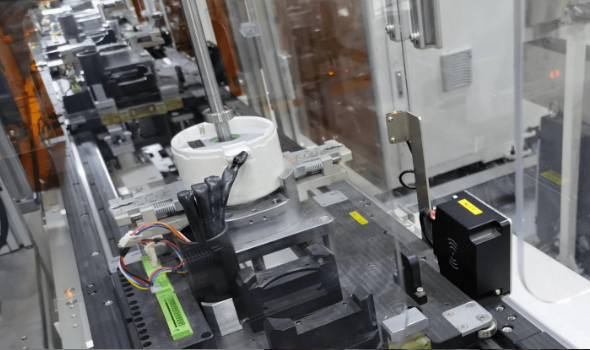

In practical applications, each cylindrical battery tray cup RFID tag and cylindrical battery possesses a unique code. The RFID reader at the feeding station enables binding between the cylindrical battery and its corresponding tray cup RFID tag. During station transfers, RFID readers installed at entry and exit points identify and read tray cup data, uploading it to the upper-level system to form traceability records. This approach enables real-time monitoring and management throughout the entire cylindrical battery production process, effectively enhancing production efficiency and product quality.

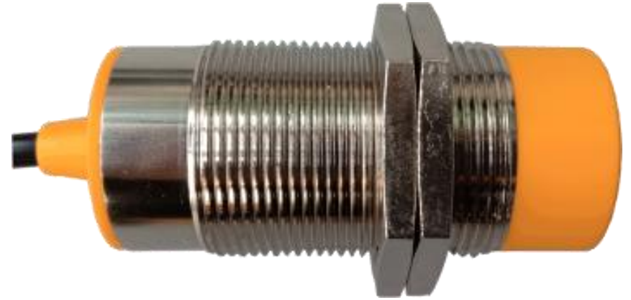

To meet the production requirements for cylindrical batteries, the RT03CK series of RFID products has been adopted. This series features the following characteristics:

- Highly Integrated Design: Combining antenna, amplifier, and controller into a single unit, this design employs advanced integrated circuit technology to achieve compact size and high performance. This high integration not only reduces the device’s volume and weight for easy installation on space-constrained production equipment but also simplifies inter-device connections, enhancing system stability and reliability.

- Convenient Installation and Flexible Deployment: Compact and structurally streamlined, the product offers versatile mounting options. It fits within the narrow spaces of drag chains, simplifying cable routing complexity.

- Standard Communication Protocols and Interfaces: Compliant with industrial communication standards including ProfiNet, EtherNet/IP, and EtherCAT, with support for Ethernet interfaces. This standardized design enables seamless communication with PLCs from multiple brands, facilitating real-time data transmission and sharing to provide timely data support for production scheduling and quality control.

- High Protection Rating: Achieves IP67 protection rating, offering exceptional waterproofing, dustproofing, oil resistance, and corrosion resistance.

- High-Speed Reading: Operating frequency matches the high-speed production cycle rates of drag chain lines.