Intelligent Asset Management

Smart Healthcare Management\Tire Management\Power Asset Management\Linen Rental Management, significantly enhancing management efficiency.

1. Smart Healthcare Management

Smart healthcare leverages IoT technology to enable interaction between patients, medical staff, healthcare institutions, and medical equipment, progressively achieving informatization and intelligence. RFID automatic identification technology offers advantages such as rapid batch reading, large information storage capacity, high security, unique identity, and non-replicability. It can record the identity of medical supplies and efficiently track information throughout their entire lifecycle—including production, transportation, warehousing, and clinical use—enabling full traceability. This prevents public healthcare safety issues and plays a vital role in the development of smart healthcare.

1.1 Medical Monitoring

Each patient wears a wristband tag. When receiving treatment, medical staff simply scan the tag with a handheld reader to access critical emergency information, such as: whether intravenous fluids are required, the name and dosage of medications to be administered, completed treatments, and any adverse reactions. All data appears before the staff in under a second, enabling them to verify medical procedures, drug specifications, and quantities. Patient tags also store comprehensive treatment histories and medication administration records. RFID technology provides a reliable, efficient, and cost-effective method for information storage and verification, ensuring emergency care is delivered promptly without delays or patient mix-ups that could lead to medical errors. Furthermore, when patient transfer is required, all relevant data—including medical history, injury type, proposed treatment methods, treatment locations, and current treatment status—can be compiled into a new tag and transmitted to the receiving hospital. Since this information can be input by simply reading the UHF RFID tag, unnecessary manual data entry is eliminated, thereby preventing human-induced errors.

1.2 Newborn Identification Management Application

Newborn infants share similar physical characteristics and lack the ability to understand or communicate effectively. Without proper identification, misidentification often occurs, resulting in irreparable consequences for all parties involved. Therefore, newborn identification must not only fulfill patient identification functions but also ensure a matched pair between mother and infant. Identifying infants alone creates management vulnerabilities and fails to prevent malicious swapping. The optimal approach is to assign paired identification tags to both the newborn and the mother, linking biological mother-infant information through means such as shared coding. During temporary transfers, both parties should undergo simultaneous verification to ensure correct mother-infant pairing.

1.3 Hospital Critical Asset and Supply Tracking and Location Application

Large medical centers typically maintain extensive storage facilities for critical medical assets and supplies. Hospital logistics staff must locate appropriate items daily from tens of thousands of stocked materials based on orders. Medical supplies often share similar outer packaging, yet their internal contents serve vastly different purposes. Consequently, hospital logistics departments frequently expend significant manpower and resources locating and verifying these items. Moreover, medical supplies must be stored according to strict protocols. During warehouse reorganizations or item relocations, misplacement incidents frequently occur, leading to widespread damage or, if released into the market, severe pharmaceutical incidents.

Therefore, an intelligent medical asset and consumables management solution is proposed: the Smart Medical Cabinet. The Smart Medical Asset and Consumables Management System establishes a collaborative platform for pharmaceutical manufacturers, hospitals, and hospital departments within the healthcare sector. It breaks down information silos in the medical supply chain, enabling real-time control over the usage and circulation of high-value medical consumables and assets. It simultaneously manages both high-value consumables and controlled pharmaceuticals, reducing waste of high-value items while ensuring the security of controlled medications. Its objective is to integrate the upstream and downstream supply chains within the pharmaceutical industry, enabling digital oversight across all stages—from formulation and production to logistics, storage, and usage. Given the vast array of medical consumables, establishing a comprehensive and stable database is essential. This database must maintain seamless communication with existing hospital systems while ensuring data security and tamper-proof integrity.

1.4 Medical Device Management

For healthcare professionals, surgical instrument management has always been a major challenge. Due to their small size, these instruments are prone to loss during storage, issuance, cleaning, sterilization, and surgical procedures. Most healthcare institutions establish specialized instrument sterilization service centers or supply departments to handle medical device sterilization. These departments are responsible for equipping various surgical instruments and equipment, managing and renting medical devices, as well as procuring or purchasing instruments, implants, and other supplies. RFID technology enables efficient rapid collection and recording of item information, facilitating electronic documentation, informatization, and automated management.

The hospital employs RFID technology to implement comprehensive automated management of surgical instruments, reducing manual inventory checks. Instead, RFID readers automatically capture data from instruments equipped with RFID tags within their reading range. This data enables analysis of blind spots and deficiencies in management processes, driving quality improvements and optimization in medical device management.

1.5 Application of Pharmaceutical Supply Chain Management

Pharmaceutical Management: By affixing electronic tags to pharmaceuticals and related items, RFID technology enables end-to-end monitoring from manufacturers to distributors and ultimately to end-users. For pharmaceutical manufacturers, RFID technology provides real-time visibility into where their products are being sold. For patients, RFID technology allows them to instantly access information such as the production date, manufacturer, and expiration date of the medications they hold.

Blood Management: RFID technology provides each blood bag with a unique identifier and stores corresponding information, which is interconnected with the backend database. The contactless identification feature of RFID also reduces the risk of blood contamination. It remains unaffected by dust, stains, or low temperatures, ensuring reliable operation in the specialized environments where blood is stored.

2. Tire Management

Many large vehicle management companies, such as bus companies, handle large quantities of internal tires with frequent turnover and high data update frequency, resulting in heavy workloads for tire management personnel. Current practices for tire usage, maintenance, retreading, and management involve manual branding for identification, followed by paper-based record-keeping of usage details. However, this approach presents significant issues: manual branding and handwritten transcription are prone to information confusion and subjective arbitrariness. It is common for a single tire to correspond to multiple identification numbers, or for multiple tires to share a single identification number, rendering tire information untraceable and unsearchable. Manual branding also damages tires and creates illegible markings. With multiple processing steps and extensive distribution channels, tire storage, delivery, and information tracking often lack oversight.

Michelin, a leading tire manufacturer, has begun embedding passive UHF EPC tags in all heavy-duty truck, coach, and bus tires while implementing corresponding RFID management systems.

2.1 Implementation Methods for Tire Labels

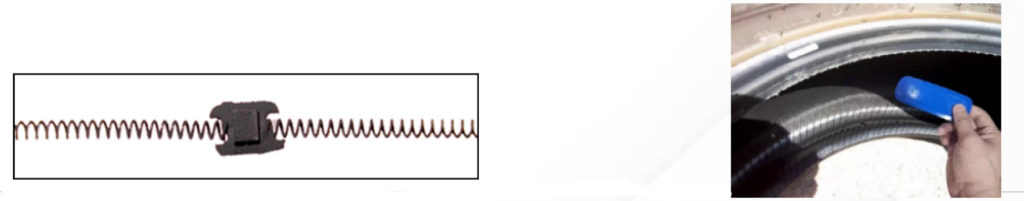

Currently, there are two methods for using electronic tags in tire management: embedding within the tire rubber and embedding within the tire inner wall. The rubber embedding method is primarily performed by tire manufacturers. The rubber and steel belts in tires can affect RFID signals, requiring these tags to feature specialized antenna designs. These designs leverage the coupling effect of internal steel belts while accounting for the material properties of rubber to ensure optimal signal transmission. The key feature of the embedded rubber method is that the tag is integrated into the tire before the curing process. Once cured, it cannot be removed. The image on the left shows an electronic tag for the embedded rubber method. At its core is a PCB substrate with a QFN-packaged UHF RFID chip soldered onto it. Two springs are attached to either side of the substrate, functioning as radiating dipole elements. The antenna’s resonant loop is implemented on the PCB substrate. Advantages of this spring-loaded tag include high temperature resistance, corrosion resistance, vibration resistance, and superior stability. The inner tire wall embedding method involves placing a rubber-based tag within the tire’s inner wall. The image on the right shows an electronic tag using this inner tire wall embedding method. The electronic tag is secured to the tire’s inner side using tire rubber. Since it does not undergo the tire vulcanization production process, its resistance to high temperatures and corrosion is significantly inferior compared to spring tags. The tire inner wall embedding method is widely used by tire management units for managing their tire assets and is commonly employed in China for bus fleet management.

2.2 Tire Label Application

In bus tire management applications, both of the above methods can be employed, each requiring a handheld device with a scanning range exceeding 50 cm. For every tire operation—such as quality inspection, fleet distribution, inventory counting, or tire mounting/dismounting—managers need only scan the tire with the handheld device to upload the operation details to the network management terminal, creating an electronic work record. Simultaneously, tires can be linked to specific buses. Each bus features a vehicle identification tag with an embedded RFID chip affixed to the lower right corner of the front windshield. During initial tire installation, the handheld device must pair the vehicle tag with the tire tag. This pairing provides reliable data for tire maintenance and retreading.

Compared to traditional methods, tire management utilizing RFID technology offers the following advantages.

- Contactless Data Collection: RFID technology significantly enhances managers’ capabilities for collecting, exchanging, and tracking information on monitored objects.

- High Security: Tag data access is password-protected, with unique identification codes that cannot be counterfeited. Tags also incorporate encryption technology, making the data highly resistant to forgery and tampering.

- Compact size and diverse shapes: Tags can be designed as spring-loaded components embedded within the tire or as small rubber inserts integrated into the internal structure.

- Reusability: RFID chips have a lifespan of up to 50 years at room temperature and support over 100,000 rewrites.

3. Electric Power Asset Management

3.1 Power Ultra-High Frequency RFID Seal Management

Electricity metering plays a crucial role within power systems, enabling the statistical tracking of electricity consumption by end-users. As a key technology supporting manual operations in this task, the management and application of electricity metering technology are of paramount importance. The application of power metering technology enhances the safety of electricity production while improving energy efficiency. As the world enters the era of the Internet of Things (IoT), nations are fully committed to building smart grids, driving the advancement of power metering technology. Corresponding equipment has achieved automation, intelligence, and informatization through IoT and RFID technology.

This enables intelligent management of power equipment operation workflows. The system features anti-counterfeiting, tamper-proofing, theft prevention, ease of inspection, infrared meter reading, and simplified maintenance management. If seals are deliberately damaged, they become unreadable, allowing issues to be detected during inspections and preventing meter tampering and electricity theft. Simultaneously, the intelligent seal management system effectively resolves issues in inspection and meter reading work, such as missed inspections, unchecked equipment, incorrect readings, estimated readings, and failure to read meters. It enhances inspection supervision and oversight, significantly reducing the management challenges associated with inspections and meter reading.

- Digital Management: Through informatized asset management of meter seals, the management level of metering equipment has been significantly enhanced.

- Enhanced Anti-Counterfeiting Performance of Power Meter Seals: Utilizing novel UHF RFID anti-counterfeiting technology significantly boosts seal security.

- Improved Anti-Theft Capabilities of Metering Equipment: Strengthened management of metering devices substantially enhances their resistance to electricity theft, thereby drastically reducing the likelihood of user tampering.

- Driving the informatization of metering equipment management: The operation of intelligent seal informatization management also complements the informatization management of other power departments, collectively advancing the informatization development of power supply companies. This has brought about a qualitative leap in the metering management level of power supply units.

- Environmental Protection: As a single-use metering seal product, this product contains no pollutants or toxic substances, is easily recyclable, and is a completely green and environmentally friendly product.

- Cost savings: The system enables digital oversight of smart seals throughout their lifecycle—from warehousing and installation to issuance and disposal—preventing waste and loss of power assets.

- Streamlined management: Facilitates intelligent oversight of internal operations, including inspection management, meter reading, and user equipment/consumption data.Digital Management: Through informatized asset management of meter seals, the management level of metering equipment has been significantly enhanced.

3.2 RFID Power Inspection System

- Grid asset tracking management utilizes RFID handheld devices to collect information from physical identifiers on-site. These devices should be selected based on factors such as anti-interference capability, read/write range, stability, and reliability. RFID technology enables automated information collection for secure grid asset management.

- In power equipment asset management, RFID automatic identification technology plays a crucial role in fixed asset management, full lifecycle asset tracking, and equipment inspection and maintenance. It significantly enhances work efficiency, reduces labor costs, and prevents various errors during inventory checks. RFID technology provides a more accurate understanding of the inventory and distribution status of fixed assets.

- Equipment inspection and maintenance focus on managing operational condition, differing from fixed asset inventory and lifecycle tracking. Due to dynamic asset states, it is closely tied to comprehensive lifecycle monitoring. The purpose of equipment maintenance is to assess operational health, promptly identify potential hazards, and address them proactively to prevent failures that could cause significant losses. Upon discovering equipment issues, inspectors must report findings promptly, accurately, clearly, and comprehensively. Relevant departments organize maintenance personnel to repair equipment and eliminate hazards based on the information provided in these reports.

- Power asset management involves numerous assets of significant value that undergo rapid updates. Management requires timely and accurate reflection of these changes, making RFID technology the most suitable solution for this purpose.

4. Linen Rental Management

Hotels, hospitals, government agencies, and professional laundry companies face the annual task of handling tens of thousands of work uniforms and linens through processes including handover, washing, ironing, sorting, and storage. Effectively tracking and managing the washing process, wash cycles, inventory status, and proper categorization of each linen item presents a significant challenge. RFID offers a perfect solution to these challenges. By embedding laundry tags into linens and linking tag information to the identified linen, real-time tracking is achieved through reader devices. This forms the core of the mainstream linen rental management systems available on the market.

The linen rental management system first assigns each piece of linen a unique digital identity tag (i.e., laundry tag). Utilizing industry-leading data collection devices, it captures real-time status information at every handover point and throughout each washing process, enabling comprehensive management across the entire lifecycle of the linen. This helps operators improve linen circulation efficiency, reduce labor costs, and enhance customer satisfaction. The rental management system maintains real-time visibility into all linen circulation stages, tracking wash cycles, laundry costs, and rental volumes/expenses across hotels and hospitals. This achieves full visualization of laundry operations, providing real-time data support for scientific enterprise management.